BRAND

All the Passion and

Technologies Belong to Hooks

BRAND CONCEPT

Provides the best products with particular, to achieve the best moments and share the excitement with anglers.

The best moment in angler's life is when they are in pursuit of an unseen fish in a nature that has yet to be encountered.

We are at the forefront of creating those best moments by accompanying anglers in their lives.

That is why we always pursue the works in particular. Seeing the world in a new way creates new emotions.

Sharing joy with them magnifies that emotion.

In order to realize this excitement, we always keep asking ourselves ”How can we make anglers happy?” and put our wisdom and skills to works.

VANFOOK will contribute to enriching anglers' lives by paying careful attention to our products with sincerity.

BRAND COMMITMENT

VANFOOK is a brand based in Banshu, a region in Hyogo Prefecture, the holy land of fishing tackle manufacturing, producing products of the highest quality.

We procure the best materials for the fishing target, use skilled craftsmen's techniques to turn them into the best products, and deliver them to anglers all over the world. VANFOOK's unique manufacturing expertise is embedded in its products, and we would like to introduce a part of it to you here.

-

Planning & Development

When it comes to materials, we have the expertise to produce the highest quality fishing hooks and metal parts.

When selecting the right material for the target species, we carefully consider every detail of the hook, thread, and parts, starting with the management of the condition of the raw material. We are also thorough in our processing methods, focusing on even the smallest details such as form, heat treatment, polishing, and plating, and we work with local partner factories as well in specific process for planning and development to achieve the world's finest finishes.

-

Design

There are so many processes involved in the manufacturing of fishing hooks and metal parts.

We design our products by simulating that all of them will be finished to the highest qualities. Depending on the product, modeling machines are used to make even the most minute adjustments.

-

Manufacturing

Although some manufacturing processes are automated, many still rely on human senses.

Human eyes and hands are used to complete each manufacturing process. Although fishing hooks, metal parts, and rigs are often thought to be simple to create, we are proud of our quality policy that we do not cut any corners on every process as it determines the quality and fishing results.

-

Quality Control

Various inspections are performed at each step of the process.

For example, visual form inspections are performed to ensure that even the smallest form defects are not overlooked. Also, we use a dedicated strength tester to check the finished strength of the hooks themselves and to ensure that there is no variation in quality, without compromise.

-

Final Inspection Before Shipment

The final inspection is also performed by human eyes.

The reason why "Made in Japan" fishing tackle is said to be the best in the world may be supported by those analog part of the process, which is to deliver excellent products by not cutting any corners until the very end of the process.

-

Material Control

We store materials such as wire, metal and thread in the dedicated storage rooms that is maintained under constant conditions regardless of the season. Wire is very delicate, and there are many different types and structures.

From its raw state, wire undergoes a structural change through heat treatment. After that, they are stored and matured for each manufacturing process until the structure becomes stable and strong enough. Our quality control is based on the idea that “iron is a living creature.”

BRAND HISTORY

VANFOOK's origins date back to the Tempo

Era of the Edo Period. (around 1830~1840)

This was just around the time of the Great Tempo Famine. In order to rebuild his livelihood, Kinbei Fujii had begun peddling textiles, purchasing fabrics from Nishijin in Kyoto and distributing them to the Harima region where he was based.

One day, Kinbei saw court nobles enjoying Ayu (Sweet Fish) fishing along the Kamo River in Kyoto and came up with the idea of producing and peddling fishing hooks and traditional fly hooks.

Returning to his hometown, Kinbei started manufacturing and selling hooks in cooperation with people in his hometown of Kurodasho, Banshu (present-day Nishiwaki City, Hyogo Prefecture) and the surrounding area.

It so happened that at the same time, Hikobei Kodera, who is called the pioneer of fishing hooks, brought back manufacturing techniques from Tosa (present-day Kochi Prefecture) and started manufacturing hooks in Shimokume (present-day, Kato City, Hyogo Prefecture), and it is documented that Kinbei started purchasing hooks from Hikobei as well.

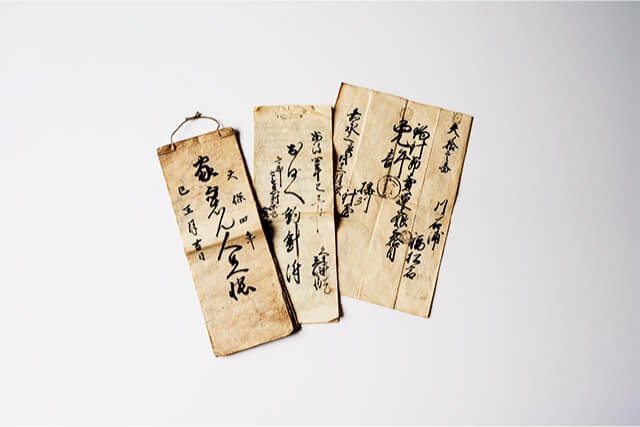

Middle: Delivery note from Hikobei Kodera

Right: Peddler's license authorized

by the Uwajima Domain (present-day Uwajima City, Ehime Prefecture) in 1850.

*The trade name at that time was Fujiya Kinbei (commonly called as Fujikin).

- 1971

-

- Changed the company name to Fujii Buichiro Shoten. *At that time, the main products were Banshu traditional fly hooks and traditional rigs.

- 2001

-

- Established VANFOOK CO., LTD. *Launched VANFOOK brand to produce lure fishing hooks

- 2007

-

- Exhibited Yokohama Fishing Show for the first time

- 2008

-

- Exhibited Efttex for the first time in Rome

- 2010

-

- Exhibited Osaka Fishing Show for the first time

- Started export, to the first overseas distributor in Australia.

- 2013

-

- Started distribution in South East Asia (Malaysia, etc.)

- 2014

-

- Started distribution in Europe (Switzerland, etc.)

- 2015

-

- Started distribution in Middle East(UAE, etc.)

- 2017

-

- Extension of the company building

- 2020

-

- Started distribution in North America (USA)

- Redesigned brand logo and Visual Identity

- Redesigned product packaging appearance

- 2021

-

- Restructured social media accounts to clarify communicate activities

- 2022

-

- Subdivided departments to clarify internal operational roles

- 2022

-

- Launched current website (Japanese version) in January

- Launched website (English version) in March

- 2023

-

- Expanded the new building